Information briefs for the week check out BMW saying the first-ever Manufacturing facility in a Field as an add-on to its manufacturing strains, cobots braving gamma rays to make medical radioisotopes, extremely dexterous, deep-sea cobots saving human divers from harsh environments, ABB does it once more with one more acquisition for AMR management, and Mujin Robotics and Accenture accomplice in hope of jumpstarting robot-AI automation in Japan.

Manufacturing facility in a Field

Manufacturing facility in a Field

Cell manufacturing simply received an attention-grabbing increase in what’s being hailed by carmaker BMW as a Manufacturing facility in a Field, which is actually a small, robot-driven manufacturing facility (with a number of industrial robots or cobots) that may simply be crated up and shipped wherever on the globe.

First conceived of and developed in Sweden in 2007, Manufacturing facility-in-a-Field Options for Availability and Mobility of Versatile Manufacturing Capability, was an answer for the belief of “cell and reconfigurable manufacturing capability on demand.” Three key options of the system have been mobility, flexibility, and pace.

.jpeg?width=440&height=213&name=1704978594749%20(1).jpeg) On the tenth Convention on Studying Factories, in 2020, Manufacturing facility in a Field, along with cell manufacturing, was offered as “a mannequin manufacturing facility—a extremely partaking and efficient studying expertise” for coaching staff in new and novel manufacturing procedures. As an alternative of many staff touring to a producing website, the location got here to them. The outcomes have been spectacular, exhibiting improved recall from contributors, and improved studying outcomes as contributors find out how and why to use new instruments and strategies not simply what they’re.”

On the tenth Convention on Studying Factories, in 2020, Manufacturing facility in a Field, along with cell manufacturing, was offered as “a mannequin manufacturing facility—a extremely partaking and efficient studying expertise” for coaching staff in new and novel manufacturing procedures. As an alternative of many staff touring to a producing website, the location got here to them. The outcomes have been spectacular, exhibiting improved recall from contributors, and improved studying outcomes as contributors find out how and why to use new instruments and strategies not simply what they’re.”

BMW just lately (2024) used the idea for a real-world software by producing the world’s first Manufacturing facility in a Field for its door meeting manufacturing line (see video).

The carmaker claims: “Manufacturing facility in a Field, the world’s first modular plug & play course of tools for door sealing functions. Developed in collaboration with AyTec Automation, it ensures a fast startup at our vegetation.”

Cobots, labs & gamma rays

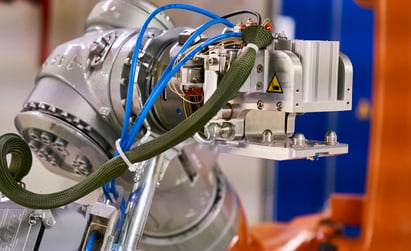

Cobots have been working their means into a variety of laboratories and demonstrating wonderful ends in practically each software. One of many newest is at Argonne Nationwide Laboratory (Chicago) on a federal authorities undertaking to see how finest to securely pace up the manufacture of medical radioisotopes by incorporating cobots, synthetic intelligence (AI) and machine studying (ML).

Medical radioisotopes are these radioactive supplies used significantly for imaging, prognosis and remedy of varied medical situations. With thousands and thousands of radioisotope remedies yearly needing preparation, gradual, costly, and oftentimes harmful manufacturing processes have been the norm. Some radioisotopes are nonetheless made primarily based on applied sciences used because the Nineteen Forties.

Medical radioisotopes are these radioactive supplies used significantly for imaging, prognosis and remedy of varied medical situations. With thousands and thousands of radioisotope remedies yearly needing preparation, gradual, costly, and oftentimes harmful manufacturing processes have been the norm. Some radioisotopes are nonetheless made primarily based on applied sciences used because the Nineteen Forties.

In apply, a radioisotope made from Iodine-131 travels all through the physique and localizes within the thyroid gland. As a result of it’s radioactive, its presence could be detected. It’s a radioactive tracer that detects a goiter, which is an irregular progress of the thyroid gland.

Consequently, in lots of instances, the demand for these rising isotopes is much past the accessible provide. This limits the speed of progress in creating these superior most cancers remedies. That’s why the combination of cobots and synthetic intelligence into the manufacturing of radioisotopes holds a lot promise.

As Argonne physicist Jerry Nolen sees it: “Simply by gaining the power to do the manipulation of the pattern from throughout the room implies that we are able to safely deal with samples as much as 10 instances as radioactive. This dramatically will increase our potential to provide these beneficial and crucial isotopes.”

6-axis, subsea cobots

Some cobots are being constructed for subsea adventures, like these from the comparatively new (2016) Sydney, Australia-based Attain Robotics.  The Attain X, for instance, is a watertight, 6-axis, underwater manipulator with 3D imaginative and prescient that may dive to 1,000 ft and has end-effector gripping accuracy of 0.39 of an inch (<1cm). …It’s dexterous gripper expertise can swiftly unzipper a duffle bag on the ocean ground.

The Attain X, for instance, is a watertight, 6-axis, underwater manipulator with 3D imaginative and prescient that may dive to 1,000 ft and has end-effector gripping accuracy of 0.39 of an inch (<1cm). …It’s dexterous gripper expertise can swiftly unzipper a duffle bag on the ocean ground.

With 75% of the globe’s floor coated in water, and with the world’s largest island/continent—Australia—surrounded by similar, Aussie subsea cobots ought to have an odds-on likelihood at doing pretty nicely as industrial merchandise. And certainly, the corporate has risen rapidly. Between its two founders (2016) and in the present day’s 50 staff (2024), Attain Robotics has constructed a shopper record of personal companies, authorities, and better schooling, in over a dozen vertical industries.

A Attain specialty is that its cobot arms are purposefully engineered for “ultra-subsea dexterity” in order that they will carry out duties usually meant for human divers. Based on its founders, that’s exactly the corporate’s mission: “extending human attain into harsh environments by creating powerful, sturdy, superior manipulation and notion techniques.”

ABB Robotics does it AGAIN!

Instantly, ABB Robotics is an autonomous cell robotic (AMR) phenom! And all of it since 2018! Whereas simply since final week, it TWICE jumped up just a few notches in management for new-age mobility in “sensible” AMRs. Well timed plan brilliantly executed.

Along with the AMRs, ABB will get a aspect profit: ABB now has a cell platform for its cobots.

Along with the AMRs, ABB will get a aspect profit: ABB now has a cell platform for its cobots.

Final week, What’s New in Robotics? reported on the ABB acquisition trifecta of Intrion (2018), and ASTI (2021), that vaulted ABB into AMR prominence; after which the January addition of Sevensence (2024) vaulting it additional into management in “sensible” AMRs.

Now comes this week’s acquisition of software program developer MeshMinds (2024) for AI, Industrial IoT, and machine imaginative and prescient. Collectively, Sevensense and MeshMinds will construct out a brand new R&D hub for revolutionary automation. These two can be joined by Austrian-based Bernecker & Rainer Industrie-Elektronik (B&R), acquired by ABB in 2017 that produces industrial PCs and manufacturing facility automation gadgets designed to extend productiveness.

Development by way of acquisition for ABB’s Robotics & Discrete Automation enterprise is how the corporate intends to catapult itself into management place in what ABB calls “subsequent technology versatile automation”.

Sami Atiya, president, ABB Robotics and Discrete Automation Enterprise was greater than happy: “AI-powered robotics and automation have the facility to remodel industries,” he mentioned, “offering companies with larger flexibility and intelligence amidst vital international tendencies and workforce challenges.”

ABB’s total boss since 2020, Björn Rosengren, promised extra acquisitions: “Among the firm’s progress will come by way of acquisitions [maybe 5 to 10 a year] notably small to medium-sized ones to assist divisions strengthen their market positions.”

AMR’s have been a lot wanted at ABB. The marketplace for autonomous cell robots (AMRs) is anticipated to develop by round 20% per yr as much as 2026, in keeping with ABB estimates, increasing from $5.5 billion in 2023 to $9.5 billion by 2026.

This charge is quicker than the one anticipated for typical fastened robots, the place ABB sees annual progress of 8%.

Mujin Robotics and Accenture to jumpstart automation in Japan

Latest analysis in Nature and from the Oxford Martin College painting Japan’s industrial automation efforts as ranging wherever from lagging to stagnating. Graeme Mcdonald at Citigroup factors out the very best automated factories in Japan are those who make robots: “Manufacturing at a few of Japan’s main robotics corporations is already practically totally automated.” However automation doesn’t lengthen a lot past robotics.

Now that synthetic intelligence (AI) and machine studying (ML) have begun to converge with robotics, Japan’s limitations have develop into obtrusive: Japanese robotics lags as AI captures international consideration, reads a header in a latest Nature article.

Now that synthetic intelligence (AI) and machine studying (ML) have begun to converge with robotics, Japan’s limitations have develop into obtrusive: Japanese robotics lags as AI captures international consideration, reads a header in a latest Nature article.

“AI and robotics aren’t separable,” says Minoru Asada, an emeritus roboticist at Osaka College. “Huge modifications occurred, and we couldn’t catch up.”

The consensus on Japan, robots, AI, and automation is that the “nation’s automation analysis would possibly want a renewed focus.” Enter Mujin Robotics and Accenture partnering with a plan to determine a “new paradigm” in automation in Japan. Mujin Robotics might be Japan’s finest instance of an AI-driven robotics vendor, and naturally, Accenture is a Dublin-based info know-how companies and consulting big to largely the International Fortune 500, with revenues for 2023 of $64.1 billion. The article in AIThority states it plainly: Accenture and Mujin Set up Joint Enterprise to Deliver AI and Robotics to the Manufacturing and Logistics Industries.

The brand new enterprise, known as Accenture Alpha Automation, will assist Japanese corporations automate their administration infrastructure with data-driven options that seamlessly mix operational information from manufacturing and logistics operations with administration information. The three way partnership is owned 70% by Accenture and 30% by Mujin.

“Mujin offers clever automation options for industrial websites. Its clever robotics platform permits corporations to deploy industrial robotics techniques with out the everyday advanced advance settings and integration, together with movement settings and peripheral tools, usually required for different robotics techniques.”

With its East Asian opponents, China and Korea, nicely forward of Japan in AI convergence, Accenture Alpha Automation will want a mighty effort to get Japan again into the sport.