Montreal/Berlin, 5 June 2024. The expertise firm Vention has analyzed in a research how firms automate their manufacturing independently. Small companies are trendsetters in do-it-yourself (DIY) automation, however giant firms are catching up. The research is predicated on anonymized information from over 1,400 company customers of Vention’s Manufacturing Automation Platform (MAP) worldwide.

For the second time, Vention publishes the annual research „The State of DIY Industrial Automation“. The main target is on do-it-yourself (DIY) automation, which permits producers of various sizes to automate their manufacturing independently utilizing state-of-the-art applied sciences.

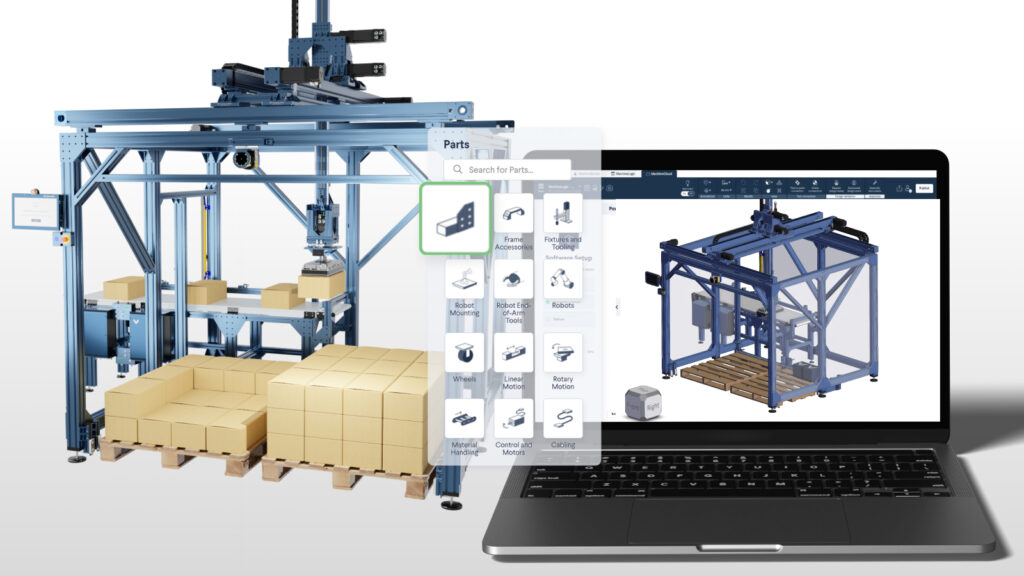

For the research, Vention evaluated the person conduct of its company clients on the Vention cloud platform MAP from January to December 2023. The intention was to seize the present state of DIY automation in firms and to elucidate how they use the DIY method for the design, integration and operation of automation elements, reminiscent of robotic cells or cobot palletizers.

„The pattern in the direction of DIY automation continues this yr,“ says Etienne Lacroix, CEO of Vention. „One driver is the scarcity of expert employees, which is turning into more and more noticeable . The query of how manufacturing will be automated rapidly and cost-effectively is at present occupying many firms. We see that small firms specifically are automating independently. However in comparison with final yr, the variety of giant firms utilizing DIY automation is rising considerably.“

A very powerful findings of the research:

1. Small (< 200 workers (MA)) and medium-sized enterprises („Medium“, < 2,000 workers) had been the main customers of automation programs on MAP in 2023, with a share of 48% and 17%, respectively. Nevertheless, small companies confronted more difficult financial situations in 2023. Because of this, there was a decline of 12% on this section in comparison with the earlier yr (see research, p. 8).

Massive firms („Massive“, < 10,000 workers) in addition to the educational and authorities analysis sector („Academia & Gov Analysis“) have made vital features in using the DIY method on MAP (+10% and +4% respectively). Platform expertise has made vital progress over the previous yr, offering extra alternatives for high-throughput initiatives historically related to bigger producers or customers (see research, p. 8).

3. In 2023, very giant firms („Enterprise“, > 10,000 workers) used the DIY method extra typically of their manufacturing facility flooring than another sector. Accordingly, the variety of initiatives carried out with MAP on this section has risen – from a mean of 4.1 in 2022 to 4.9 initiatives in 2023 (see research, p. 11).

4. Initiatives with machine operation purposes had been the quickest carried out on MAP in 2023. That is seemingly attributable to the truth that it’s troublesome for firms to recruit workers given the continuing labor shortages. As latest improvements have made CNC integration extra accessible, producers are extra keen than ever to rapidly undertake automated machine operation purposes (see research, p. 24).

5. After two years of report gross sales (2021 and 2022), the Affiliation for Advancing Automation (A3) reported a major 30% decline in robotic gross sales in North America in 2023. In distinction, robotic deployments on MAP noticed a notable enhance in each 2022 and 2023. In 2023, robotic deployments on MAP grew by about 40% (see research, p. 26).

The complete research will be discovered right here.

Ähnliche Beiträge